EFC is excited to announce a new product addition and premier supplier with the addition of ITW Formex® Flame Retardant Materials.

EFC is excited to announce a new product addition and premier supplier with the addition of ITW Formex® Flame Retardant Materials.

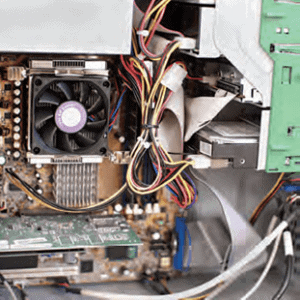

ITW Formex® polypropylene and polycarbonate flame retardant electrical insulating materials provide superior electric surge shielding in automotive, industrial and consumer electronic equipment.

EFC provides Formex™ materials as sheets or rolls and can be fabricated into a wide range of shapes to meet the flammability and dielectric needs of your application.

Product Advantages And Benefits:

- Meets global safety standards

- Ultra-low moisture absorption

- Maintains mechanical/electrical properties

- Shields electricity from electric surge

- Parts will not crack or split

- Lower overall part cost with thinner materials

- Dissipates static electrical charge to a ground

- Parts can be easily designed to incorporate a number of joining and fastening methods, often eliminating external fasteners

No other flame retardant, electrical insulating material can match the flexibility and performance of Formex for cost-effective fabricated parts. Formex has successfully replaced a variety of electrical papers, thermoplastic materials, and injected molded parts.

Formex materials provide new and unique options for the design and construction of low-cost internal mechanical components. Fabricated internal parts, such as air flow baffles and wire harness organizers, are commonly used a s cost-effective replacements for plastic injection molded or sheet metal components.

Major industries:

- Electrical Vehicles (EV)

- Solar Energy/Solar Power Inverting (PV)

- Non EV Automotive

- Cloud Data Centers

- Industrial Controls

- LED Lighting

- Electrical power Distribution

- Consumer Electronics

- Major Appliances

- Medical Electronics

- Information Technology

- Telecommunications

Click here to download the solutions flyer.

Contact EFC for samples or questions!