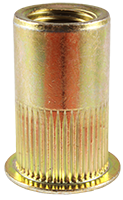

Rivet Nuts

Rivet Nuts

Ideally Suited For Tubing, Extrusion, & Other Similar Types Of Single Sided Applications.

FEATURES & BENEFITS

- Do not need welding to the base material. Expensive environmental and welding equipment not necessary.

- Can be placed “blind” — no access to back of material required.

- Prepainted material can be used. Will not damage paint in the installation process.

- Installed quickly and accurately with inexpensive, easy-to-use tooling. Hand tools, spin-spin and spin-pull tools.

- Can be removed without damaging base material.

- Available up to 3/4-10 and M16.

- Variety of head styles—flat, thin, and countersunk.

- Variety of body types—round (smooth and knurled), half hex and full hex.

- Variety of materials—steel, stainless steel, aluminum, and brass.

RIVET NUTS CAN REPLACE:

- Nuts & Bolts — requires access to both sides of the material. Nuts can be lost and create

longer assembly time. - Clinch Nuts — requires access to the backside of the material and an expensive press

must be used when installing into sheet metal. - Weld Nuts — Requires expensive welding equipment and can cause material weakness

by burning the base material. Cannot be added to finished parts. - Rivets— Permanent fastening method; not allowing for removal of components.

- Thread Tapping/Cutting Screws — weaker thread strength than rivet nuts.

- Heated Drill & Tap — weaker; same disadvantages as weld nuts.

Item # |

Grip Range |

Hole Size |

Thread Size |

|---|---|---|---|

| 06A0200541-96R1 06A0200541-96R1/Asset/06A000310-TCS.png | Grip Range N/A .70 to 4.2 mm | Hole Size N/A 9.53 to 9.68 (Hex) mm | Thread Size N/A M6 x 1.0-6H |